Our Fab Shop

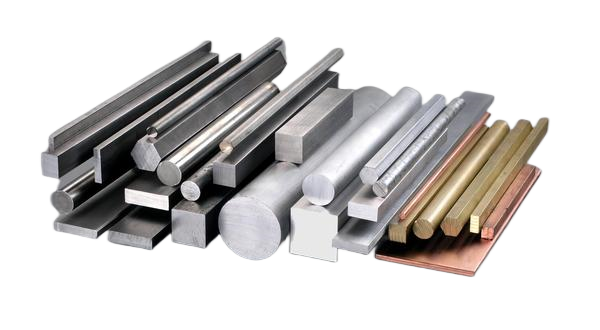

We Provide Quality Manufacturing Services

Manufacturing Facility

Packaging Inspection Area

Product Placement Area